Efficient Production of Large Volume Product Catalogs

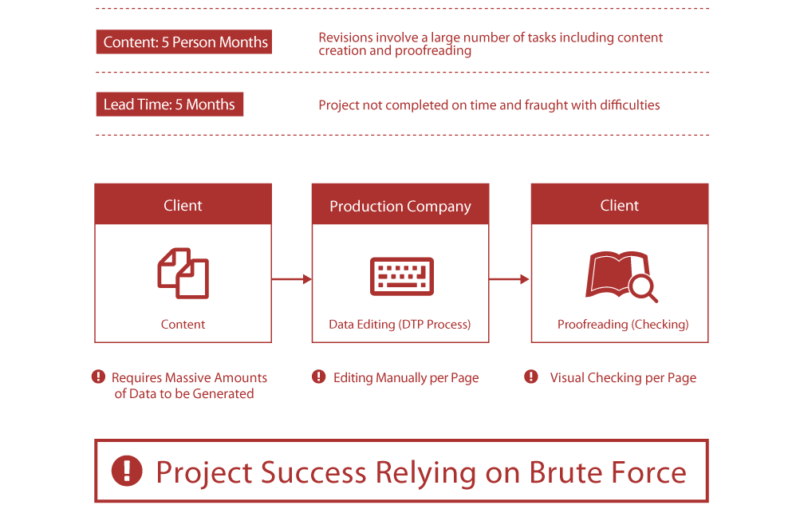

Client A is a manufacturer of industrial components, offering more than 800 products. Due to the large number of products, a revision of its product catalogs is extremely labor-intensive and requires a great deal of time, therefore forcing its personnel to work overtime for an unreasonably long period of time to meet revision deadlines.

- Client

- Industrial Component Manufacturer

- Product

- General Product Catalog (Paper-based)

- Total Products Listed

- 800 Products

- Total Pages in Catalog

- 1100 pages